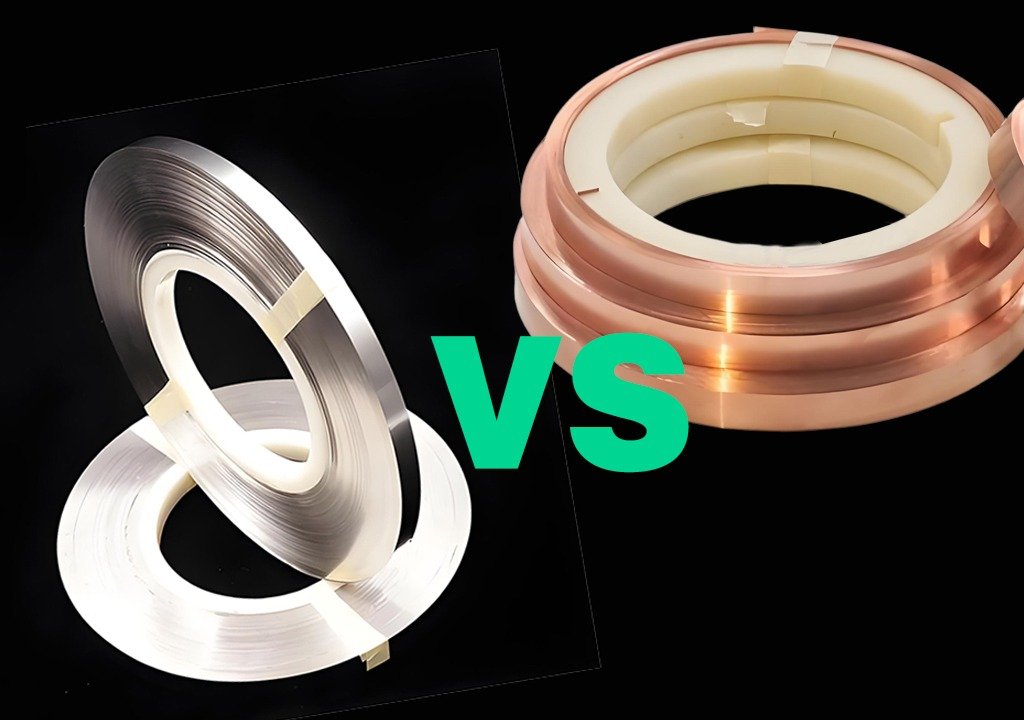

When you build a battery pack, every part is important. The metal strips that connect the battery cells are crucial. These connectors, known as interconnects, directly impact the battery’s power, safety, and lifespan.

The two most common materials for these strips are nickel and copper.

These two metals have very different properties. One is known for being durable and reliable. The other is known for high performance but needs more careful handling.

This guide will explain everything you need to know about using nickel and copper strips for batteries. We will look at their good points and bad points, explain how to work with them, and help you decide which material is right for your project.

1. Understanding the Nickel & Copper Material

Before we compare nickel and copper, it is important to understand what they are. Learning their basic properties will help you make a better choice.

What is Nickel? A Durable and Stable Metal

Nickel is a strong and reliable material. It is a silvery-white metal known for its strength and excellent ability to resist rust and decay.

Key Properties: Hard, can be stretched without breaking (ductile), and has a high melting point.

For batteries, nickel’s main advantage is its long-term stability. It does not corrode easily, even in damp conditions or when exposed to chemicals from the battery. This stability helps the electrical connections inside the battery pack stay clean and work well for many years. This makes nickel a very popular material for reliable, long-lasting battery packs.

What is Copper? The Best Metal for Conducting Electricity

Copper is the best common material for moving electricity. It is the reddish-brown metal used in most electrical wires because it allows electricity and heat to flow through it with very little resistance.

Key Properties: Soft, easy to bend and shape (malleable), and an excellent conductor of heat and electricity.

For battery use, copper’s main benefit is its high performance. Because electricity flows through it so easily, it helps send more power to your device and wastes less energy. However, copper can tarnish or oxidize when it is exposed to air. This oxidation can reduce its performance over time if it is not protected.

2. A Direct Comparison: Nickel Strips vs. Copper Strips

Now, let’s compare these two metals based on the factors that are most important for building a battery pack.

(1) Electrical Conductivity: How Well Electricity Flows

This is the area where Copper Strips has a clear advantage.

Copper’s ability to conduct electricity is about 4 to 5 times better than pure nickel’s. This means copper has much lower electrical resistance. With low resistance, more of your battery’s energy goes to powering your device instead of being lost as heat.

What this means for your battery:

Less Wasted Energy: Low resistance in copper means less energy is wasted. This makes the battery more efficient.

Handles More Current: You can send more electricity through a copper strip of the same size without it getting too hot. This is very important for devices that need a lot of power, like power tools or electric cars.

Nickel is not as conductive as copper, but it works well enough for many common battery packs. It is a good choice for devices that do not draw a large amount of power.

(2) Corrosion Resistance: How Well It Lasts

This is the area where nickel has the clear advantage.

Nickel is very good at resisting corrosion and rust. It forms a natural protective surface that keeps it safe from moisture and other elements. This is very important for a battery pack, which needs to work well for many years. A connection that does not corrode will maintain low resistance and ensure the battery performs well over its entire life.

Copper, however, can easily oxidize. When exposed to air, it can form a green layer of tarnish. This layer does not conduct electricity well and can cause the connection’s resistance to increase. Higher resistance leads to more heat and lower battery performance.

To prevent this, copper strips often need to be covered with a protective coating, such as nickel. This adds another step and more cost to the building process.

(3) Thermal Performance: How It Handles Heat

Heat can damage a battery. Both nickel and copper help manage heat, but they do it in different ways.

Copper’s Thermal Conductivity: Copper is excellent at moving heat. It can pull heat away from the battery cells, which helps keep them at a safe temperature.

Nickel’s Thermal Stability: Nickel performs very well at high temperatures. It stays strong and does not lose its shape when it gets hot. This is an important safety feature that helps prevent battery failure.

(4) Mechanical Strength: How Strong Is It

A battery pack must be strong enough to handle vibrations and movement without falling apart.

Nickel is a harder and stronger metal than copper. This makes it more durable and better at resisting physical stress during assembly and use.

Copper is softer and easier to bend. This can be helpful for making custom shapes, but it also means copper is more easily damaged.

3. How to Build with Nickel Strips and Copper Strips

The differences between these metals become very clear when you start to build a battery pack. One of the biggest differences is how easy they are to weld.

Weldability: A Key Difference for Builders

Spot welding is the most common way to attach metal strips to battery cells. It uses a quick burst of high electrical current to generate heat and melt the metal, creating a solid connection.

Nickel is very easy to spot weld. Because it has higher electrical resistance, it heats up quickly at the weld points. This creates strong and consistent welds with little effort. Most spot welders available to the public can easily weld pure nickel strips.

Copper is very difficult to spot weld directly. The same low resistance that makes it a great conductor also makes it hard to weld. The electricity and heat spread out too quickly, so it’s hard to create enough focused heat to make a good weld. Using a standard spot welder on pure copper often creates weak connections that can fail.

The “Copper-Nickel Sandwich” Technique

Since copper is hard to weld, builders use a special technique. It is often called the “copper-nickel sandwich.”

This is how it is done:

A small tab of pure nickel or nickel-plated steel is placed on top of the copper strip, right where the weld needs to be.

The spot weld is then performed on the nickel tab.

The nickel tab heats up and melts, and the intense heat it creates is enough to melt the copper underneath it. This fuses the copper strip securely to the battery terminal.

This technique allows you to use high-conductivity copper with a standard welding process. However, there are some extra requirements:

A More Powerful Welder: This technique often requires a better, more powerful spot welder.

More Skill: It takes practice to make good, consistent welds using this method.

Extra Materials: You must have the small nickel tabs for the process.

Cost: Looking at the Full Picture

If you only look at the price of the metal itself, copper is usually cheaper than pure nickel. However, you must consider the total cost of using each material.

| Cost Factor | Pure Copper | Pure Nickel |

| Material Price | Usually Lower | Usually Higher |

| Extra Processing | May need nickel plating to prevent rust, which adds cost. | No extra processing is needed. |

| Labor & Tools | Harder to weld. May need a better welder and more time. | Easy to weld with standard tools, which saves time. |

| Total Cost | Can be higher when you add plating and extra labor costs. | Often the more cost-effective choice for standard packs. |

When you include the cost of protective plating and the more difficult welding process, using copper can sometimes cost as much or more than using pure nickel, which is a simpler material to work with.

4. Other Options and an Important Warning

The choice is not just between pure nickel and pure copper. There are other materials available, including one you should be very careful with.

Nickel-Plated Copper: A Combination of Strengths

This material is a copper strip that is coated with a thin layer of nickel. It offers a combination of the best features of both metals:

A Copper Center: Provides excellent electrical conductivity.

A Nickel Outside: Provides excellent corrosion resistance and makes it easy to weld.

Nickel-plated copper strips are a great choice for high-performance battery packs that need both high power and long-term durability. They solve the main problems of using either pure nickel or pure copper by themselves.

A Serious Warning: Avoid Nickel-Plated Steel for Carrying Current

You can often find very cheap strips called “nickel-plated steel.” You must be extremely careful with this material. It is not safe to use as the main connector in a battery pack.

The reason is that the center of the strip is steel, and steel is a very poor conductor of electricity compared to nickel and copper.

| Material | How Well It Conducts Electricity |

| Pure Copper | Excellent (100%) |

| Pure Nickel | Good (20-25% as good as Copper) |

| Steel | Very Poor (3-7% as good as Copper) |

If you use nickel-plated steel strips to carry the current in your battery pack, the high resistance of the steel will cause major problems, including:

Wasted Power: A lot of your battery’s energy will be lost as heat.

Dangerous Heat: The strips can get very hot, creating a serious fire hazard.

Bad Performance: Your device will not get the power it needs.

The only safe use for nickel-plated steel is for the small tabs in the “copper-nickel sandwich” welding technique. Never use it as the main material to carry electricity in your battery pack.

5. How to Choose the Right Material

After learning about these materials, how do you decide which one to use? The best choice always depends on what you need for your specific project. Here are some clear recommendations to help you decide.

You should choose PURE NICKEL strips if:

- Your main goals are reliability and a long lifespan.

- You are building a battery for a device that uses a standard or low-to-medium amount of power. Examples include power banks, portable radios, solar lights, or backup systems.

- The battery might be used in a damp or humid location.

- You are using a standard or basic spot welder.

- You want the easiest and most straightforward building process.

You should choose PURE COPPER strips (and use the sandwich method) if:

- Your main goal is to get the highest possible performance and efficiency.

- You are building a battery for a device that needs a large amount of power. Examples include electric cars, e-bikes, powerful drones, or high-performance power tools.

- It is very important to keep the battery as cool as possible.

- You have a high-quality, powerful spot welder, and you are comfortable with a more advanced building technique.

- The battery needs to be small and compact, and you do not have enough space to use wider or thicker nickel strips to handle the high power.

You should choose NICKEL-PLATED COPPER strips if:

You want a high-performance material that balances the benefits of both nickel and copper.

Your project needs both high electrical conductivity and excellent corrosion resistance.

You want better performance than pure nickel, but an easier welding process than pure copper.

You are building a premium-quality battery pack where the final performance is more important than the cost of materials.

To make the decision even easier, you can use this simple guide:

| If Your Main Priority Is… | Then Your Best Choice Is: |

| Ease of Use & Reliability | Pure Nickel |

| Maximum Power & Efficiency | Pure Copper (with sandwich weld) |

| A Balance of Performance & Durability | Nickel-Plated Copper |

| Working with a Basic Welder | Pure Nickel |

| Long-Term Use in Any Environment | Pure Nickel |

Now that you understand the key differences in conductivity, corrosion resistance, weldability, and cost, you have the knowledge to make an expert decision. You can choose the material that will help you build a battery pack that is powerful, efficient, safe, and made to last.